The SMPD application is designed for measuring logs and cut pieces, and for controlling roundwood sorting lines.

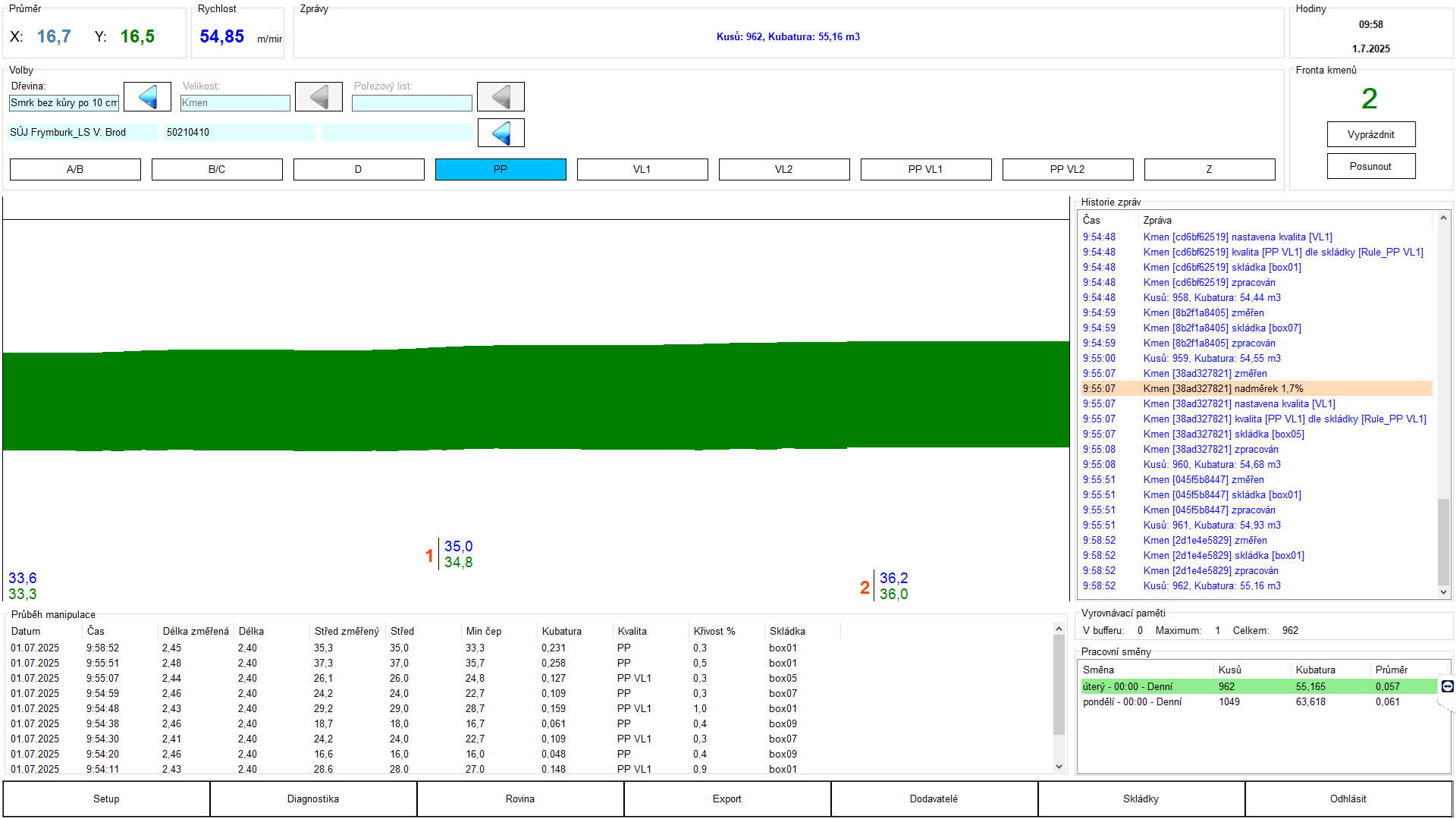

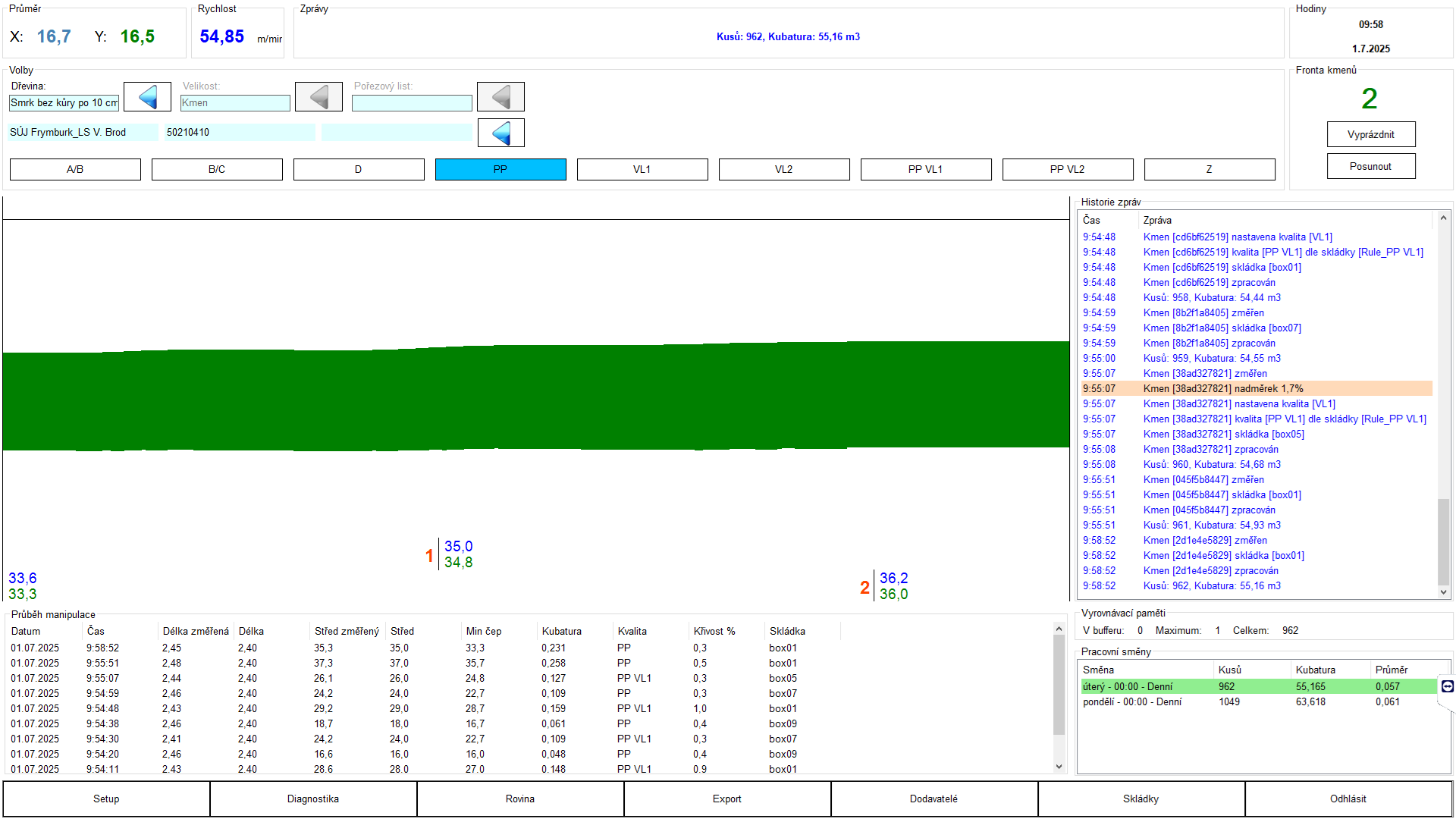

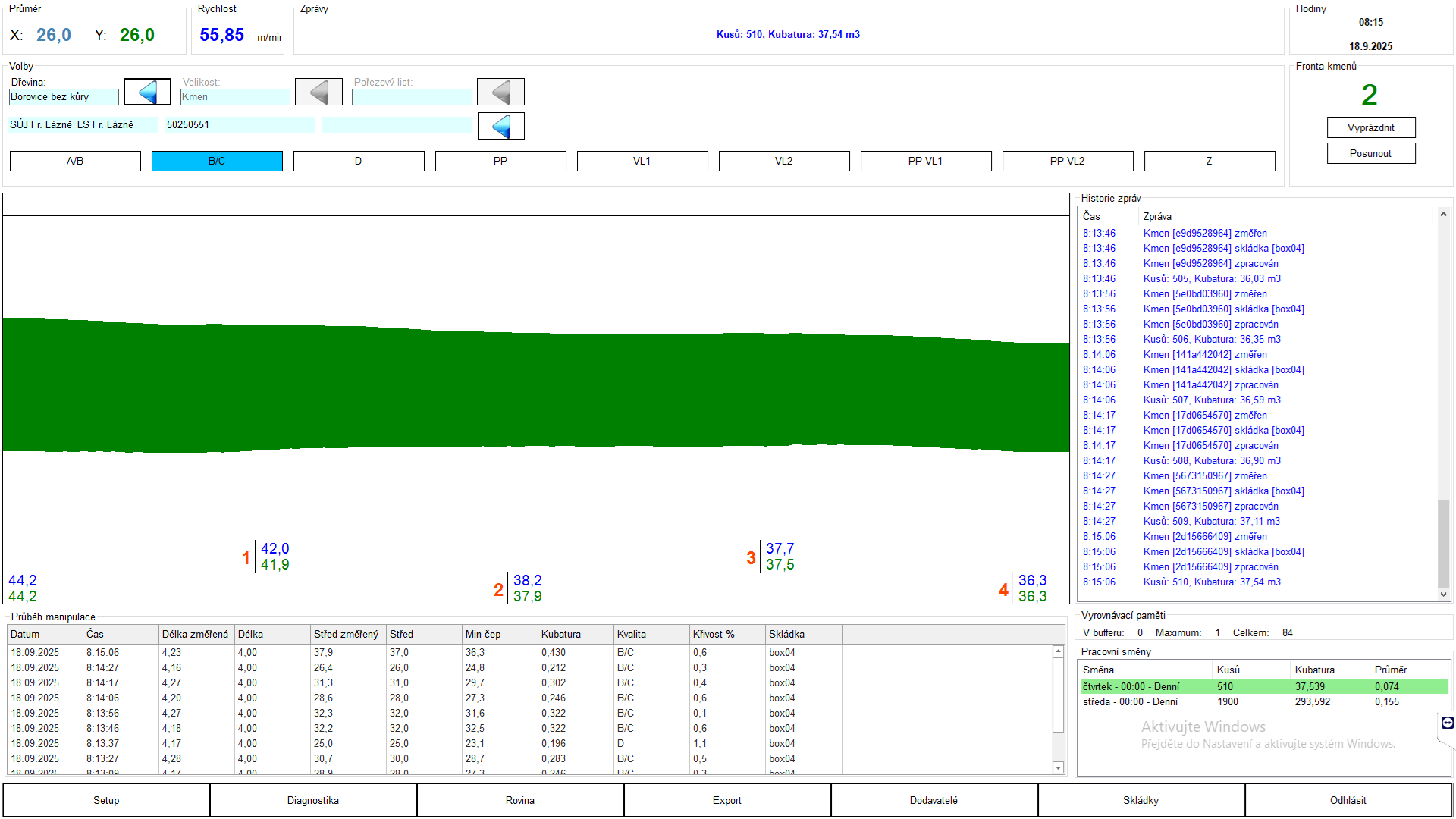

Each log is automatically measured, digitally analyzed, and its parameters—such as length, diameter, sweep, and others—are calculated. The species and basic quality are assigned by the operator. Based on the identified parameters, the log is sorted to the appropriate storage area, to which it is transported via the sorting line.

Application Features

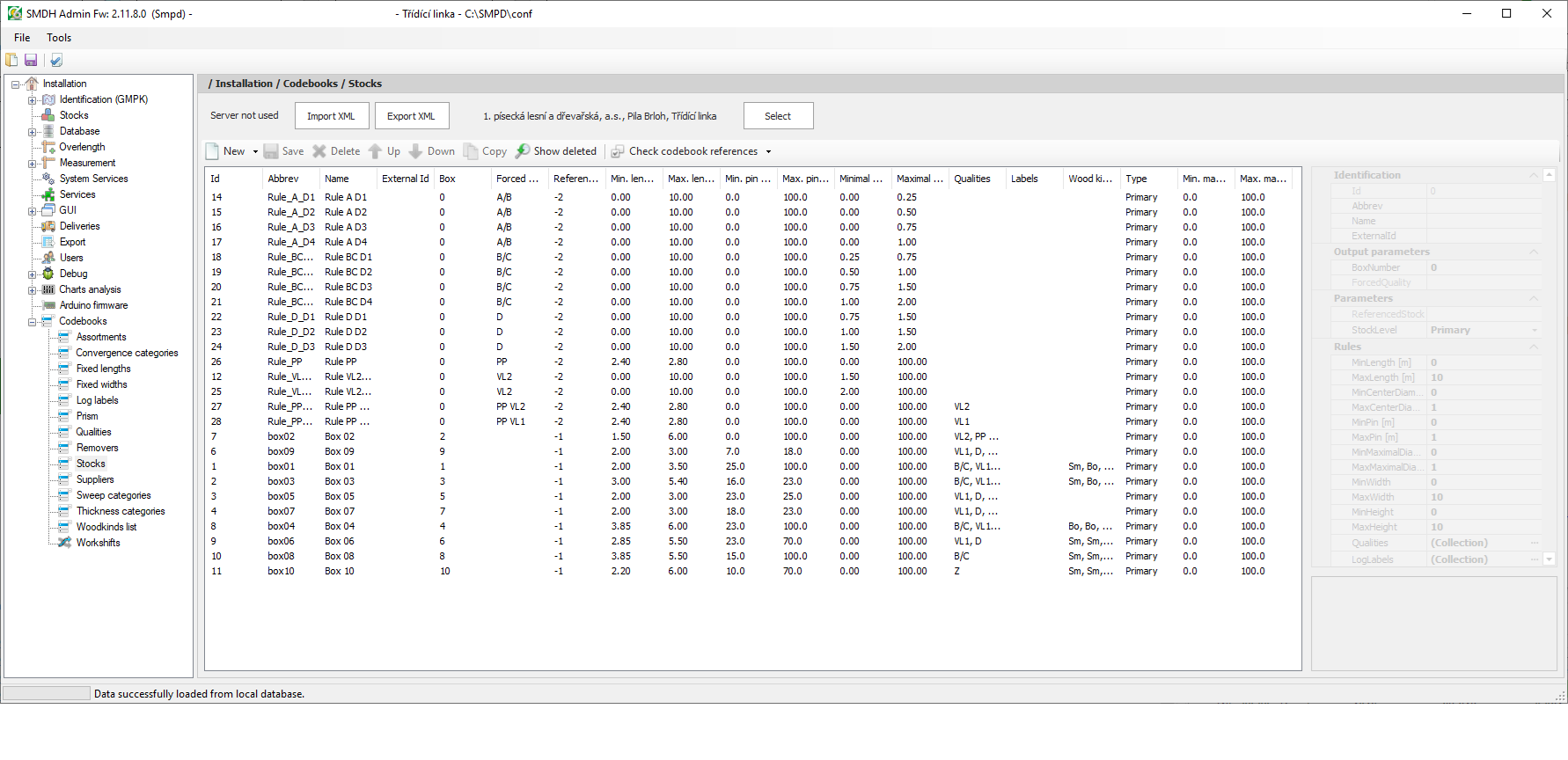

Sorting rules can be adapted to meet nearly any requirements.

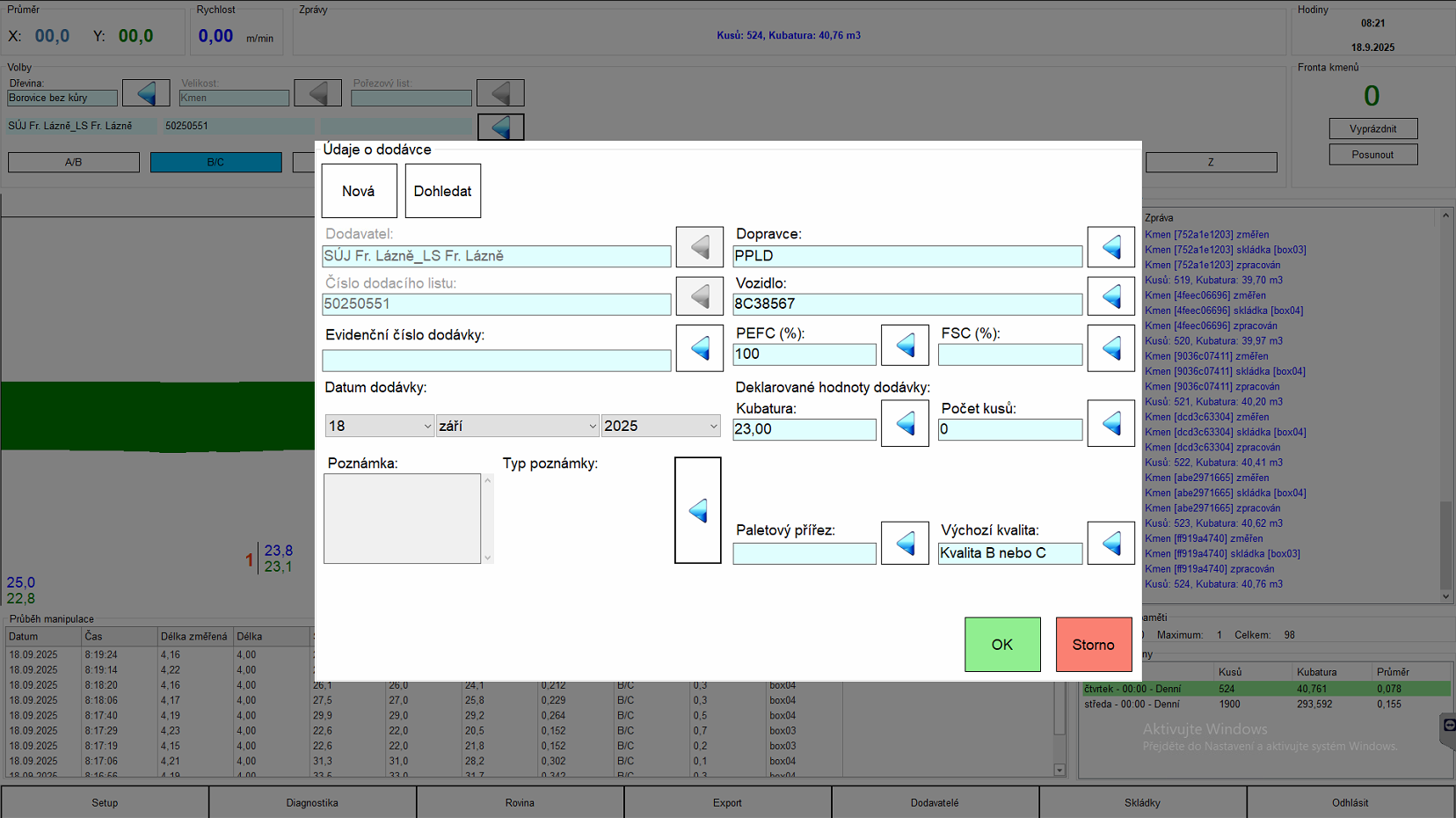

Each log is recorded in a database that can be accessed remotely, for example, from an office. A supplier and delivery note can be assigned to each log, which allows the measurement output to be used for invoicing.

Thanks to its modular design, the measuring application can be integrated with almost any sorting line—whether manually operated or automated lines that lack detailed measurement records or analysis capabilities.

The SMPD application, combined with suitable measuring hardware, can significantly improve the efficiency of even older sorting lines, digitize roundwood tracking, and simplify invoicing and administrative processes.

The SMPD measuring software can also be connected to other devices such as metal detectors or cameras for photographing measured logs.