The application is designed to simplify the process of measuring and cutting logs in a log yard more efficient and convenient.

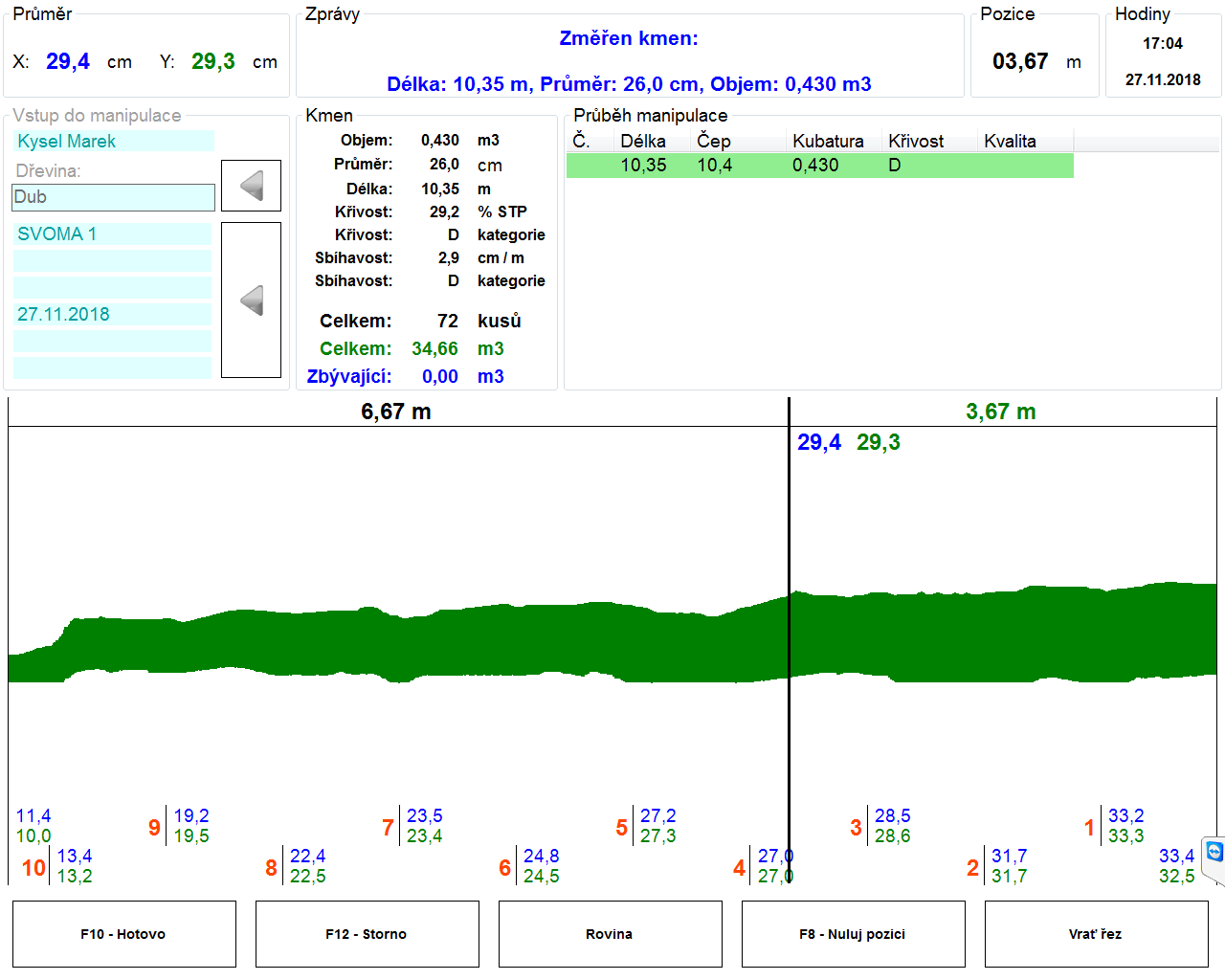

The delivered log or cutout is measured using electronic non-contact measuring system and is clearly displayed to the operator on the control panel, including all necessary parameters such as length, center diameter, volume, sweep etc.

During handling, the control panel shows at which point of the log the cut will be made, including the current data on the diameter of the log at the point of cut.

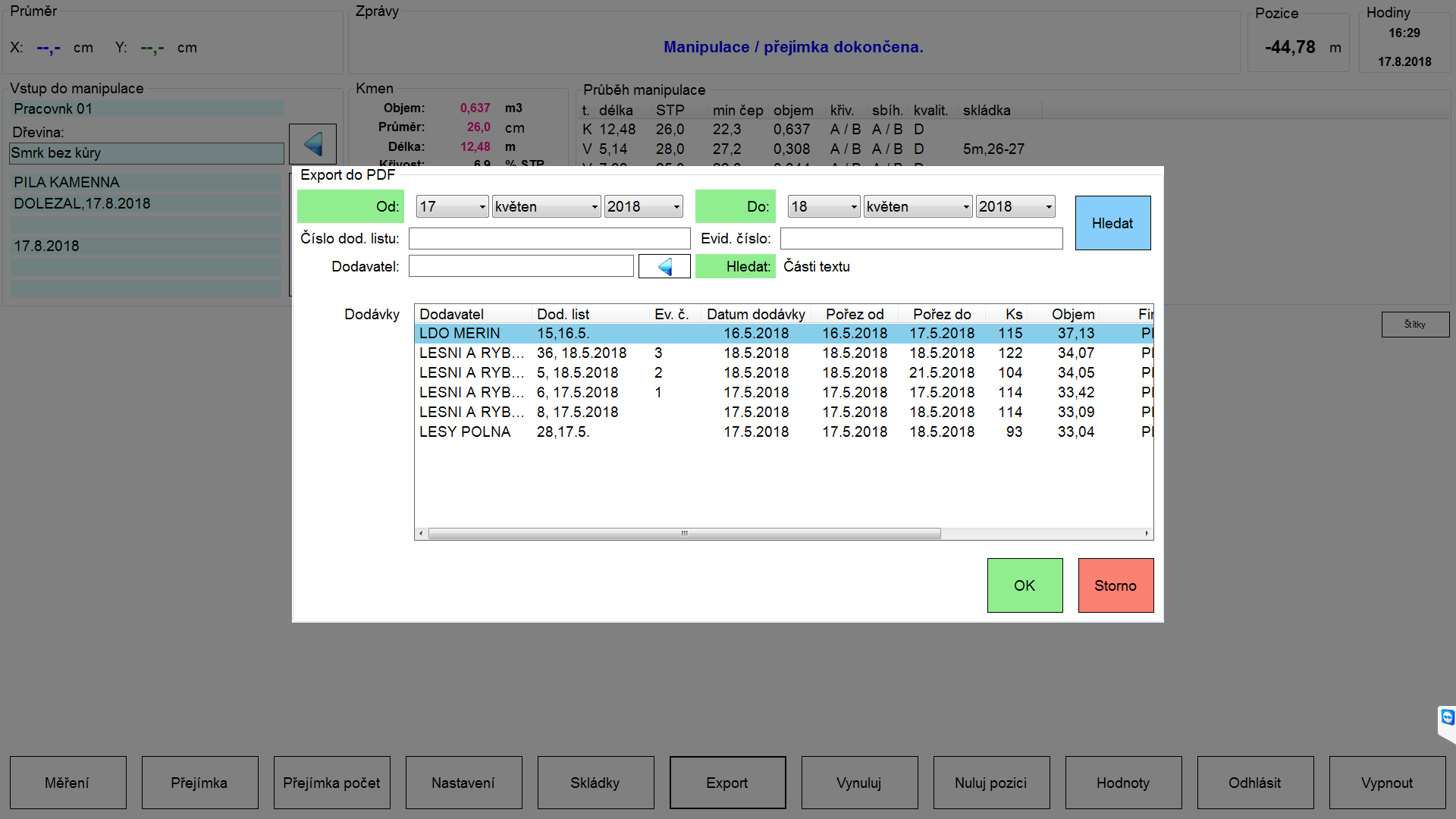

All parameters of all logs and cut logs are stored in the database for later reporting.

Application Properties

- measurement and manipulation of logs and cutouts

- records of logs and cutouts on delivery notes

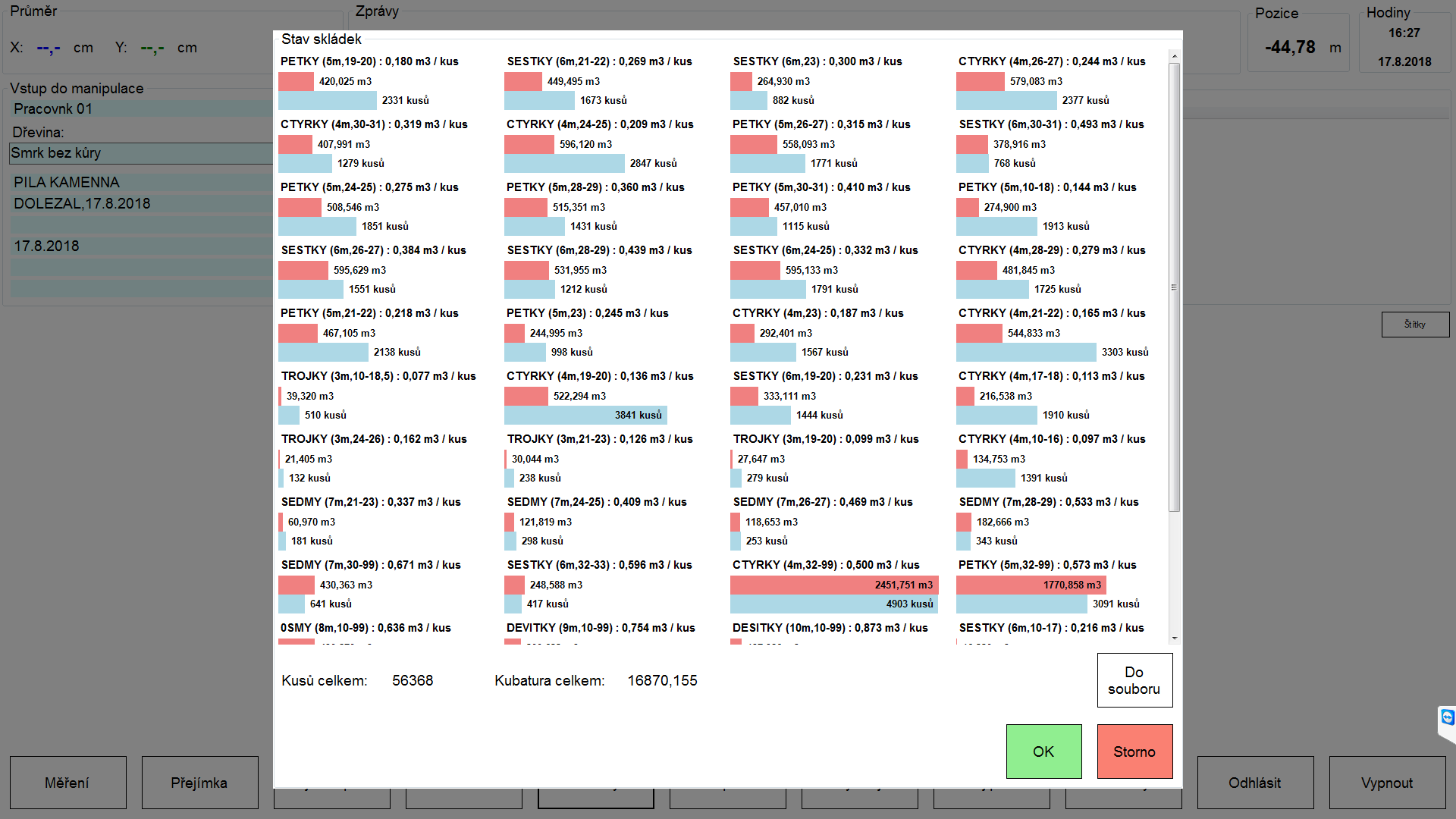

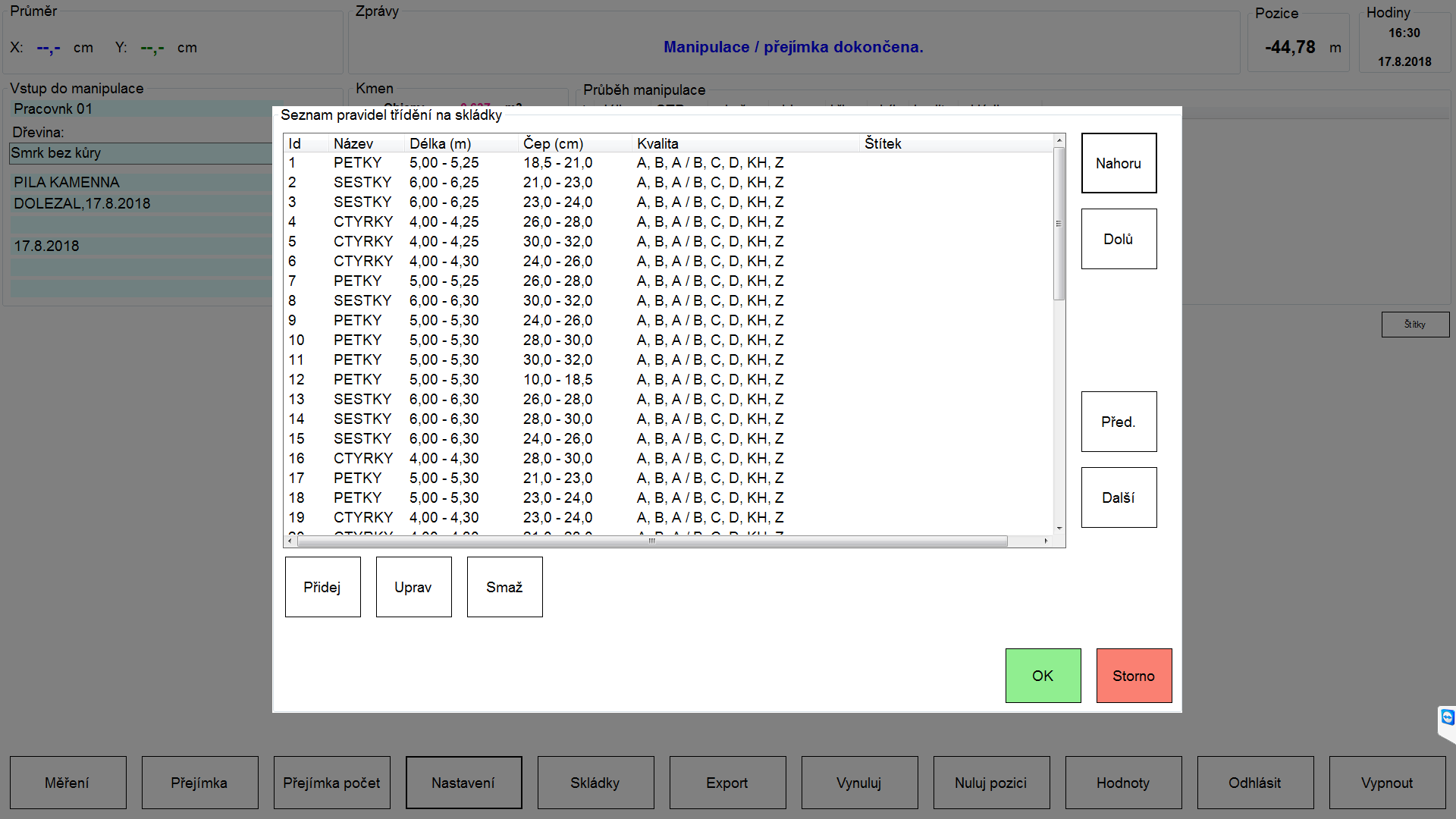

- records of cutouts in stocks

- automatic data transfer to the office

Measuring Properties

The diameter is measured in two axes perpendicular to each other along the entire length of the log at least every 3 cm.

The length is measured from the movement of the sawmill line.

- vertical axis with an accuracy of ± 0.5 cm

- horizontal axis with an accuracy of ±1,0 cm

- length with an accuracy of 1 %