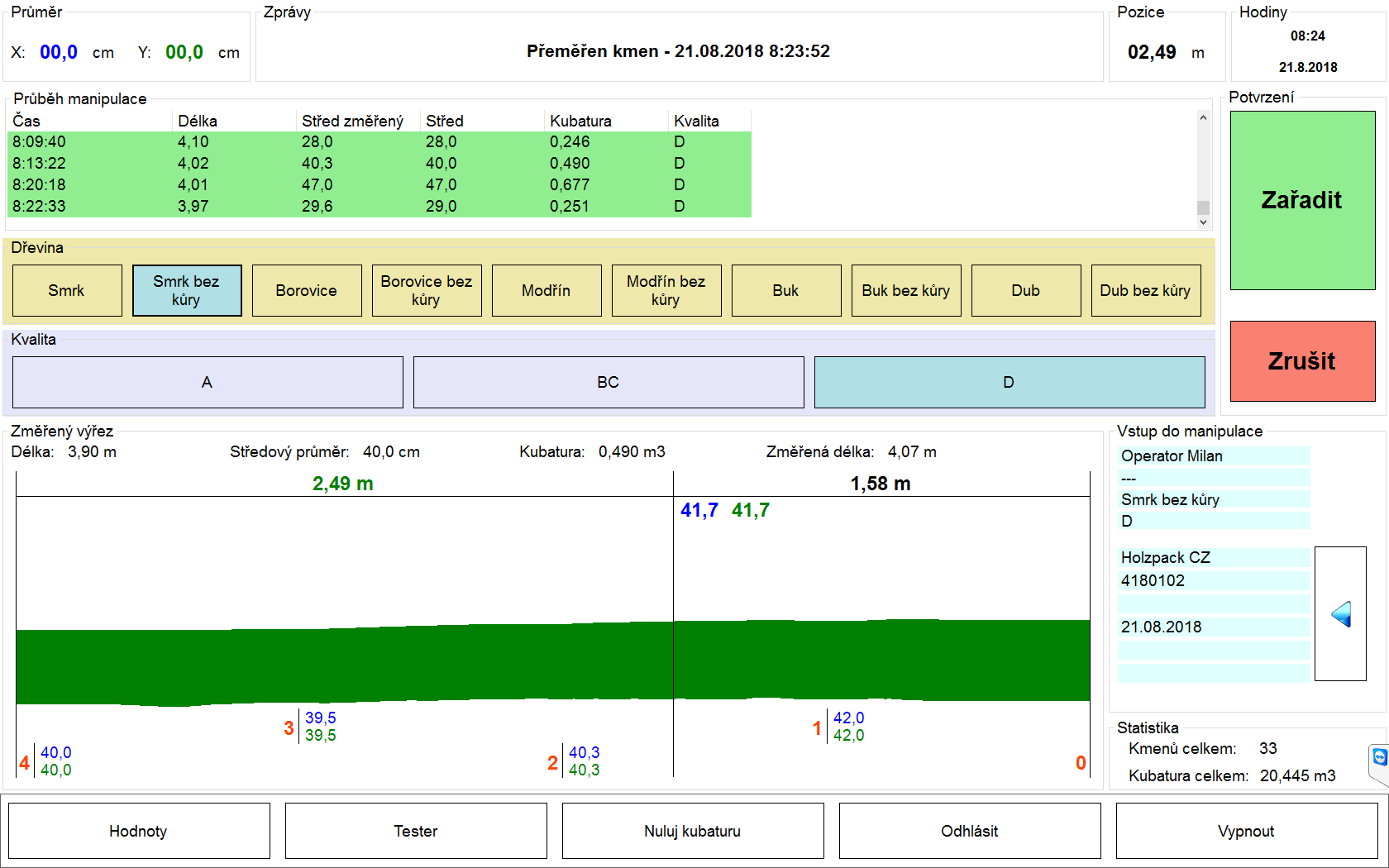

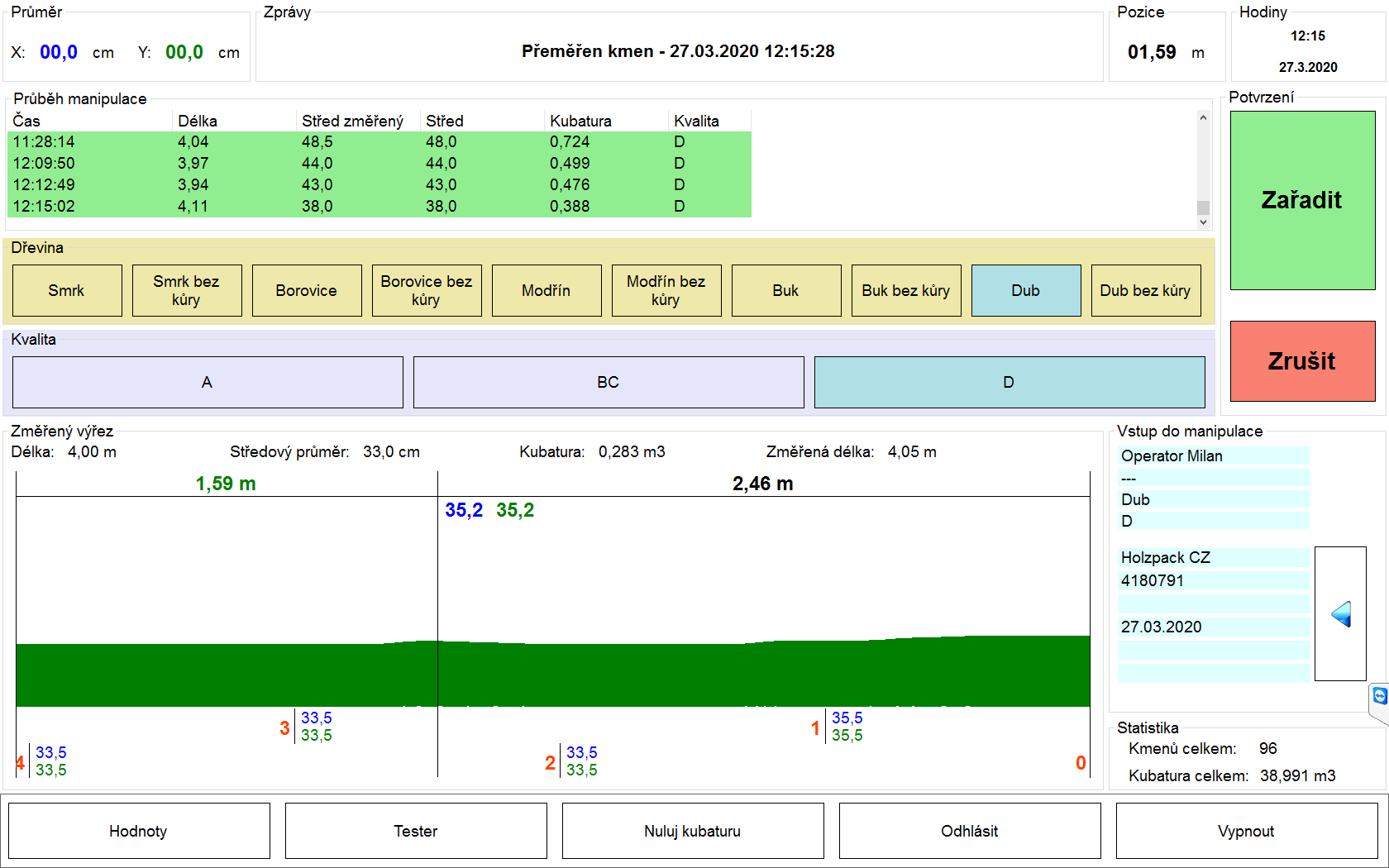

The application is designed to measure the number of pieces and cubature of logs during log processing on a band saw.

The measuring device is installed on a stationary part of the machine and the log is measured during cutting. The operator selects the tree species and the quality of the log before the processing is completed. Each measured piece is registered in a database.Application Properties

- measurement of logs during cutting

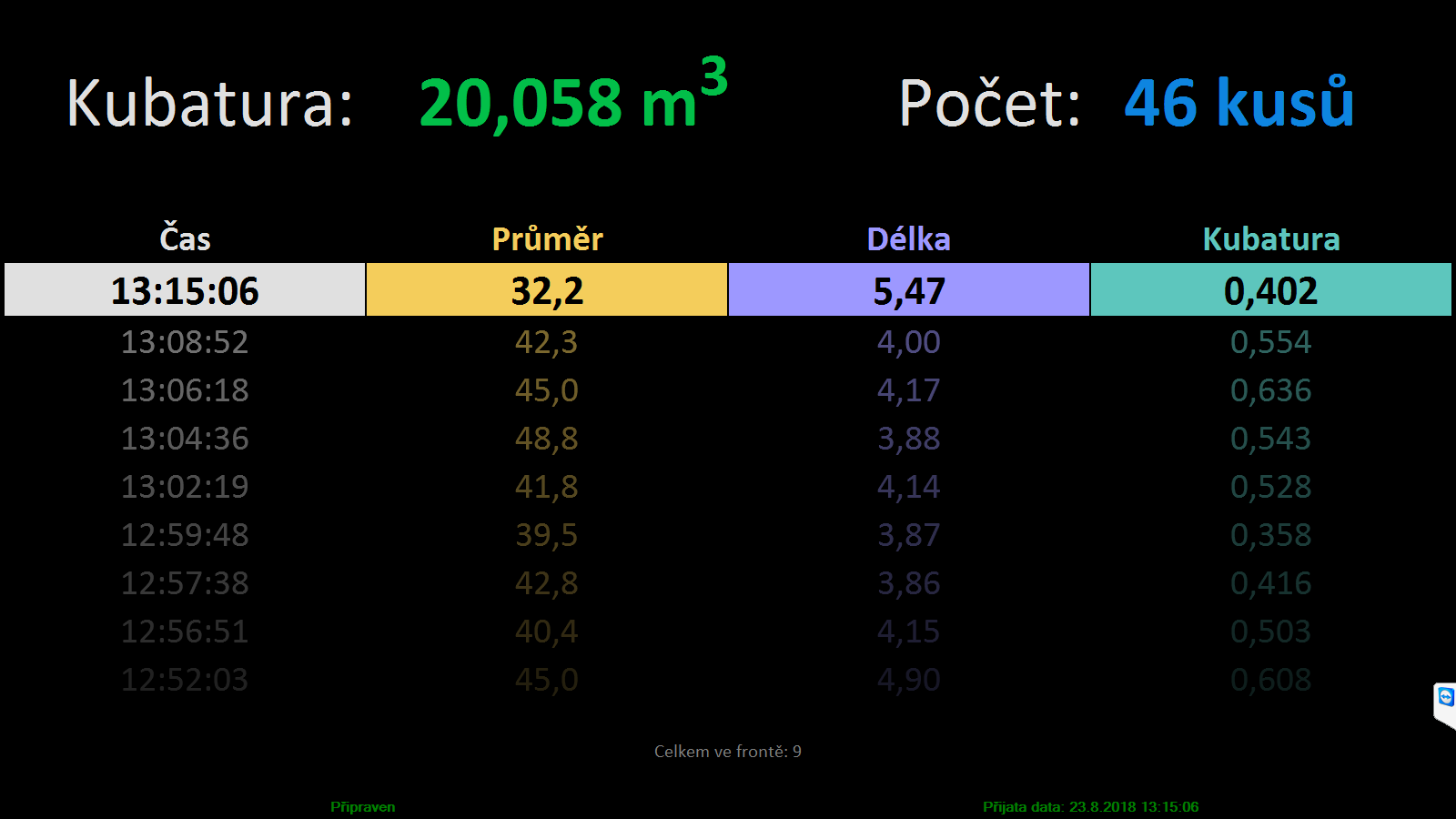

- records of logs and cut-outs on delivery notes

- automatic data transfer to the office

Measuring Properties

Diameter is measured in vertical axes in the full length of the log at least every 5 cm. Length is measured by the movement of the carriage.

- vertical axis with an accuracy of ±1,0 cm

- length with an accuracy of 2 %