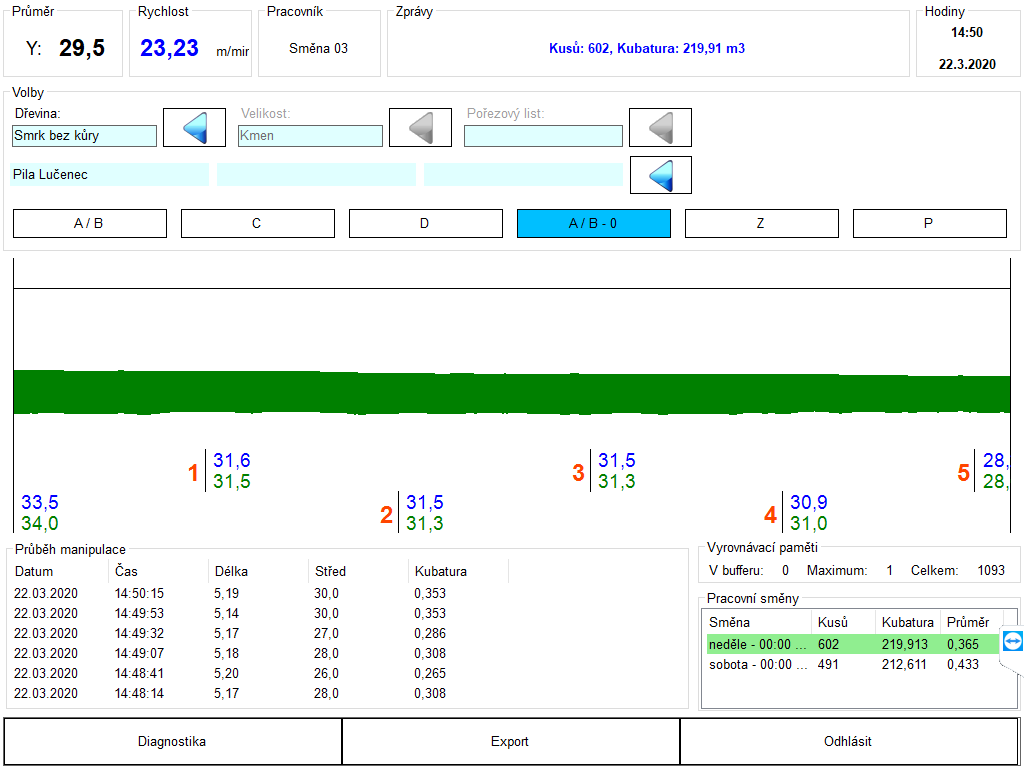

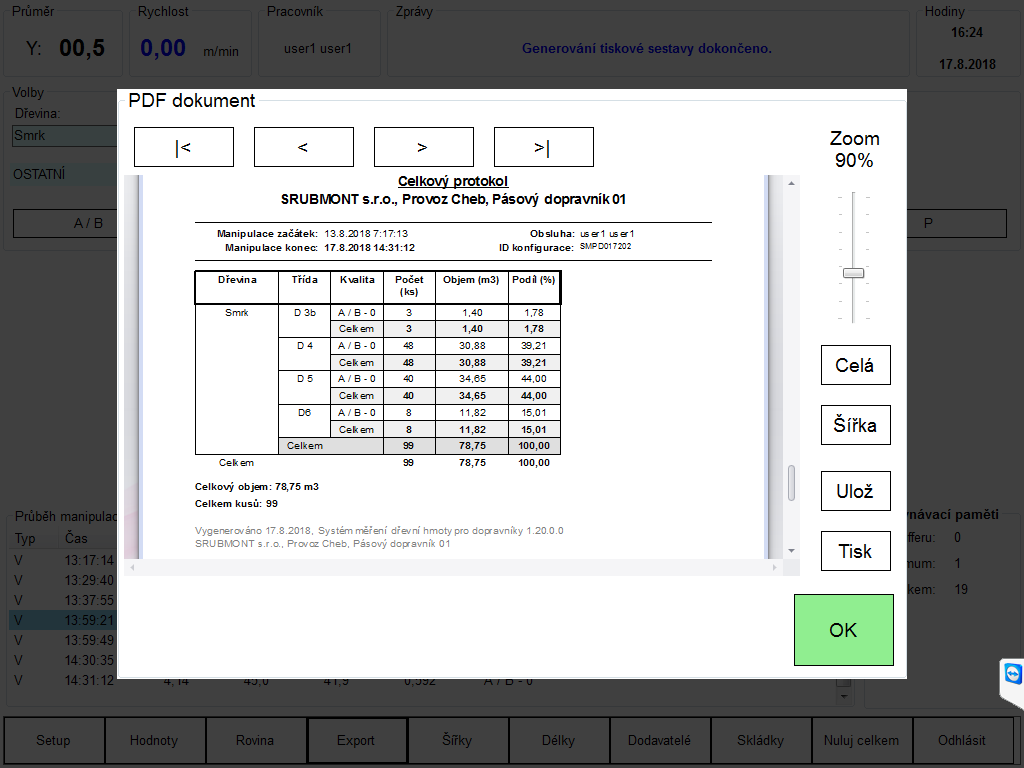

Application for measuring logs and cut-outs moved by a belt or other conveyor.

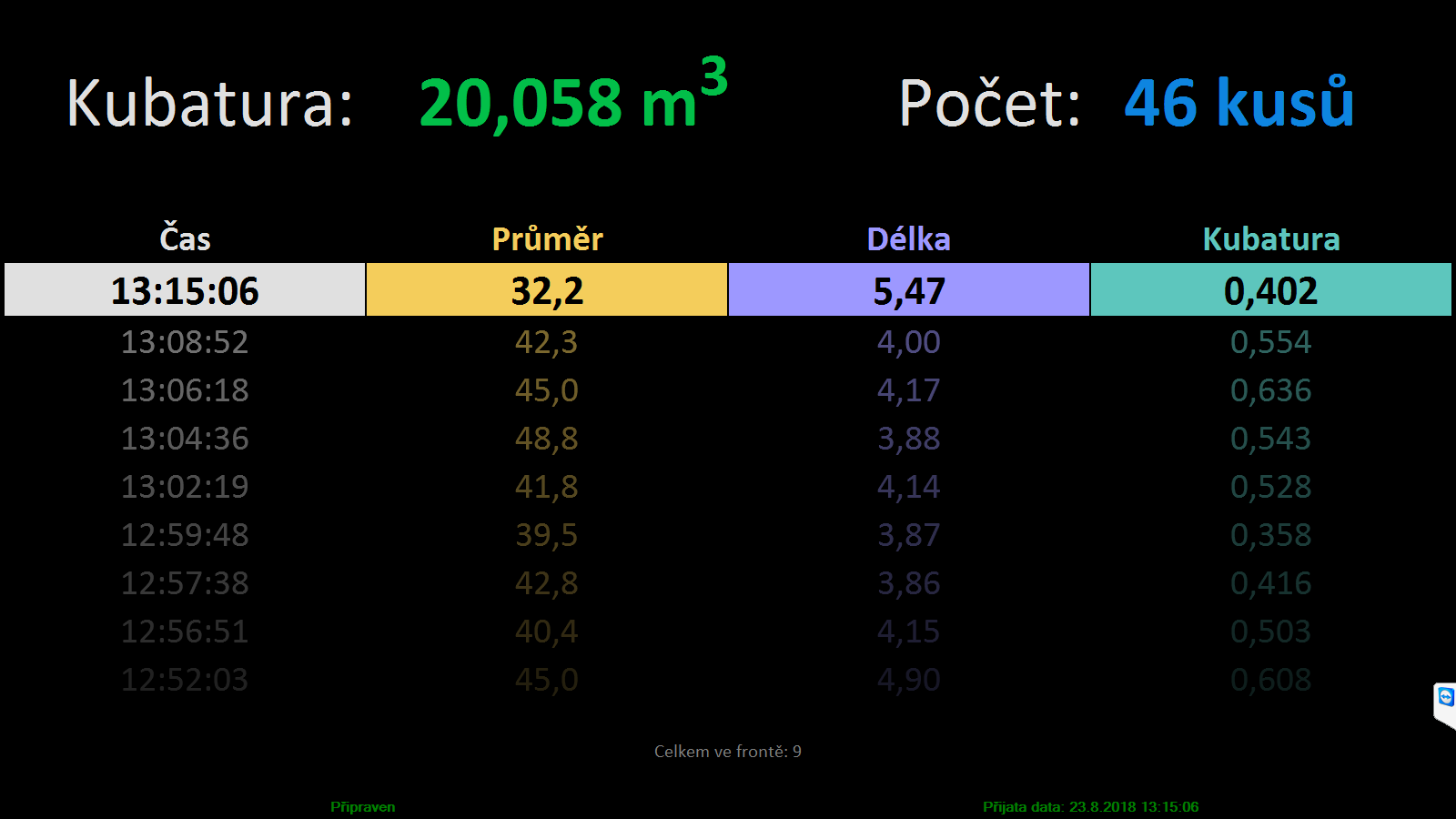

Each measured log and cutout is registered in the database. The total number of pieces and the total wood volume per shift is displayed on a light display or monitor so that workers have an immediate overview of their work performance

Application Properties

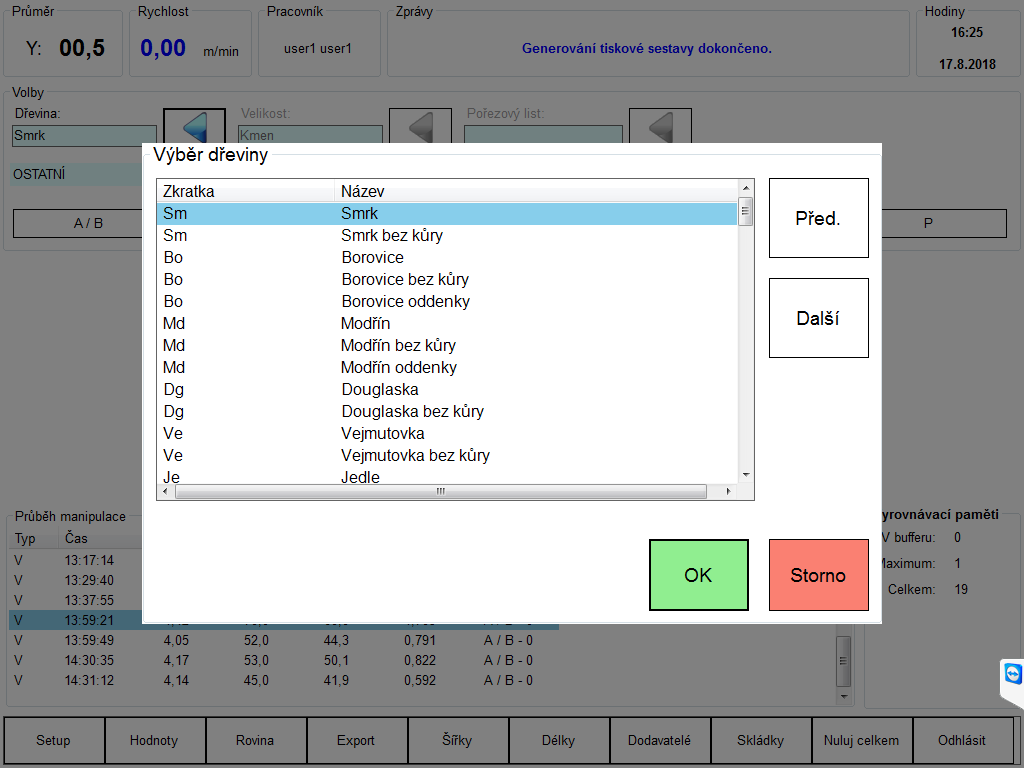

- measurement of logs, cutouts, prisms and boards

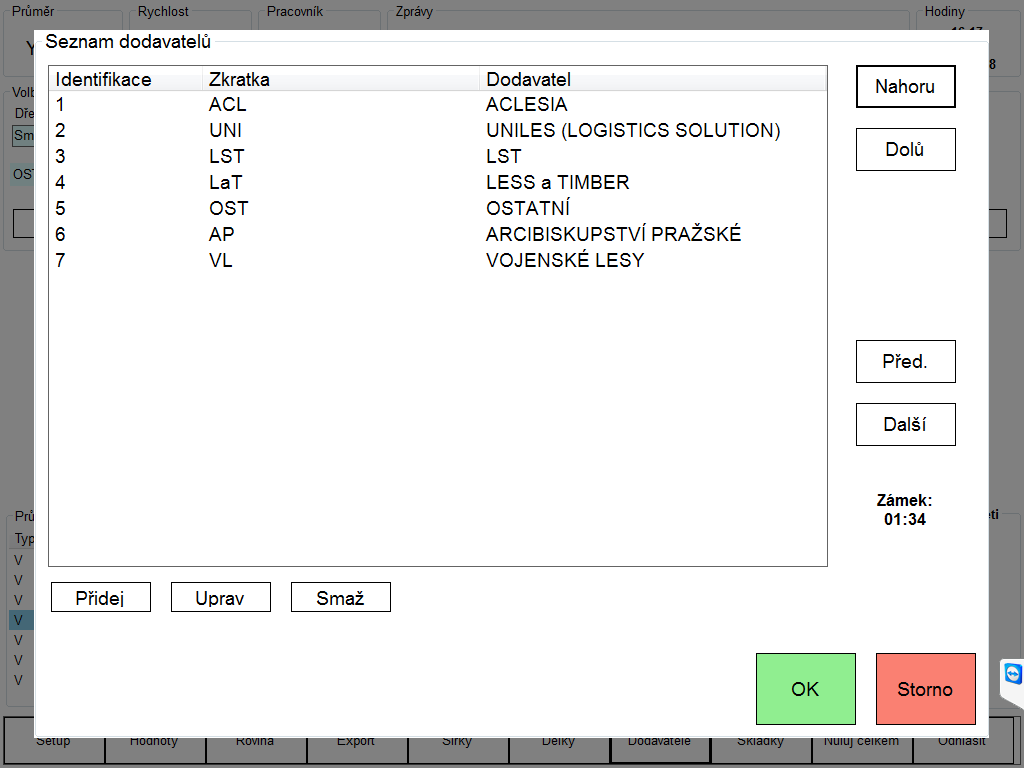

- automatic data transfer to the office

Measuring Properties

The diameter is measured in two axes perpendicular to each other along the entire length of the log at least every 3 cm.

The length is measured from the movement of the belt conveyor.

- vertical axis with an accuracy of ± 0.5 cm

- horizontal axis with an accuracy of ±1,0 cm

- length with an accuracy of 1 %