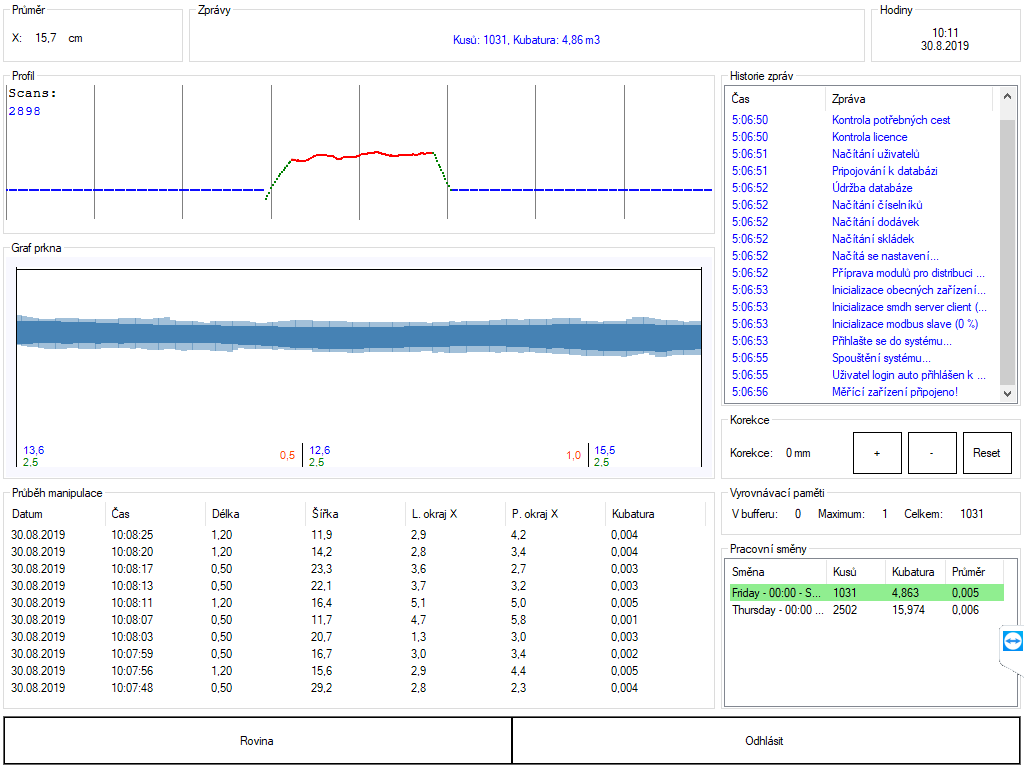

The application is designed for automatic measuring and edging of the raw boards. Before entering the saw edger, the surface of the board is measured and the width of the saw edger is set on the basis of the measured data.

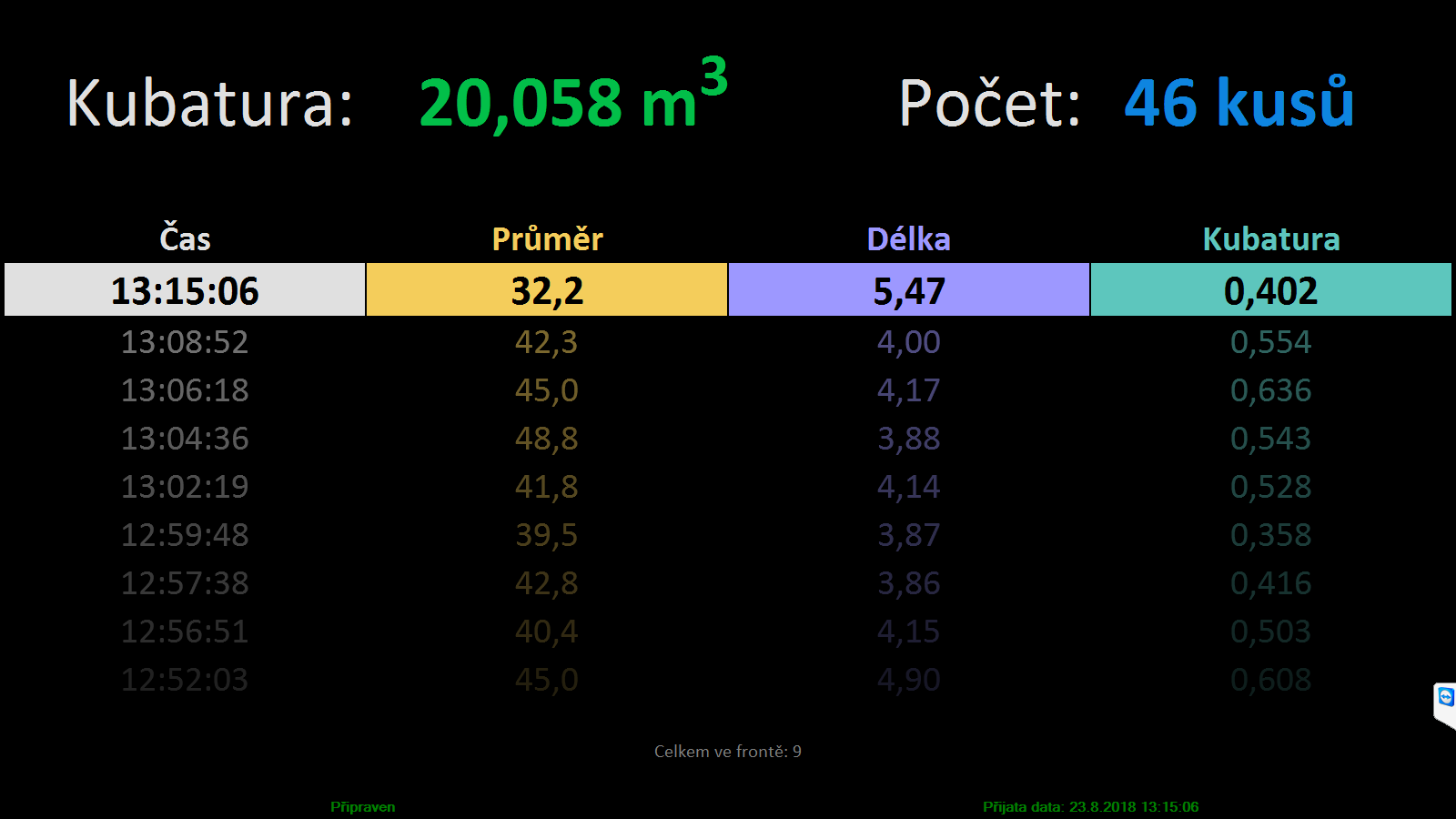

The system works completely automatically. Each measured piece is registered in the database, including all resulting parameters such as length, minimal board width, edge dimensions etc. The total number of pieces and the total wood volume per shift is displayed on a light display or monitor.

Application Properties

- measurement of processed boards

- control of the edging machine

- automatic data transfer to the office

Measuring Properties

The measurement of the board width is performed by a profile laser along the entire length of the board. The length of the board is measured from the movement of the conveyor. It is also possible to measure the board thickness.

- board width with an accuracy of ±1,0 cm

- board thickness with an accuracy of ±0,3 cm

- length with an accuracy of 1 %